1.2mm pitch Crimp terminals or Compression terminals for mx 78172

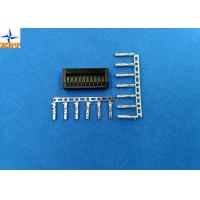

Receptacle Housings

Specifiaction:

General information:

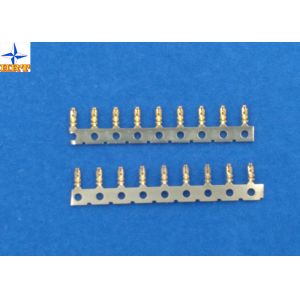

Category: Crimp Terminals

Series: A1201-GPE

Application:Signal

Physical information:

Gender: Female

Material :Phosphor Bronze

Finish:Gold-flash

Packaging Type: Reel

Termination Interface: Style Crimp or Compression

Wire Insulation Diameter: 0.80mm

Electrical & Mechanical information:

Current Rating: 1A AC, DC

Voltage Rating: 125V AC, DC

Contact Resistance: 30mΩ Max

Insulation Resistance: 100MΩ Min

Withstanding Voltage: 500V AC/minute

Temperature range: -25℃ to 85 ℃

Quality:

The world's class xinpei Plastic& metal electronic Co.,Ltd.to

provide customers with high efficiency service responsibility,

forge ahead, the endess pursuit

Except the plating ,From Design tooling, stamping ,Injection

molding, assemble, Testing ,packing .All the

step are doing by ourself. So we can control the quality.

1. Manufactured under strict controls.

2. ISO 9001:2008

3. UL Certification

4. Reach Cetitifaction

5. RoHS compliance

6. OEM or ODM project for customer

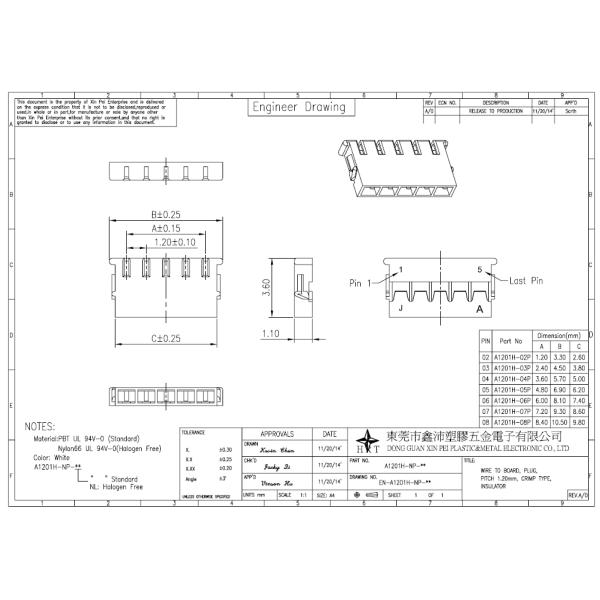

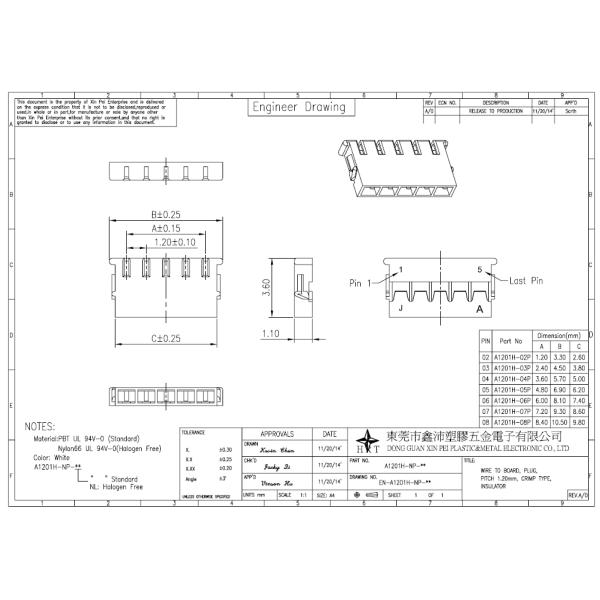

Drawing & testing report:

Please kindly check the following information to order right

products.

3. Ratings & Applicable Wires

| Item | Standard | | Rated Voltage (Max.) | 50V AC/DC | | | Rated Current (Max.) And Applicable Wires | AWG#28 | 1.5A AC/DC | | AWG#30 | 1.0A AC/DC | | Ambient Temperature Range | -25℃ ~ +85℃* |

*: Including terminal temperature rise

4. Electrical Performance

| Test Description | Procedure | Requirement | | 4-1 |

Contact Resistance

| Mate connectors, measure by dry circuit, 20mV max., 10mA.(Based

upon JIS C5402 5.4) | 20mΩ (Max.) | | 4-2 | Insulation Resistance | Mate connectors, apply 500V DC between adjacent terminal or ground.

(Based upon JIS C5402 5.2/MIL-STD-202 Method 302 Cond. B) | 100MΩ (Min.) | | 4-3 | Dielectric Withstanding Voltage | Mate connectors, apply 500V AC (rms) for 1 minute between adjacent

terminal or ground. (Based upon JIS C5402 5.1/MIL-STD-202 Method

301) | No Breakdown. | | 4-4 | Contact Resistance on Crimped Portion | Crimp the applicable wire on to the terminal, measure by dry

circuit, 20mV (Max.)., 10mA. | 5mΩ (Max.) |

5. Mechanical Performance

| Test Description | Procedure | Requirement | | 5-1 | Actuator Insertion & Withdrawal Force | Insert and withdraw connectors at the speed rate of 25±3mm /

minute. | Refer to paragraph 7 | | 5-2 | Crimping Pull Out Force | Fix the crimped terminal, apply axial pull out force on the wire at

the speed rat of 25±3mm / minute.(Based upon JIS C5402 6.8) | AWG#28 | 0.9kgf (Min) | | AWG#30 | 0.7kgf (Min) | | 5-3 | Terminal Insertion Force. | Insert the crimped terminal into the housing. | 1.50kgf (Max.) | | 5-4 | Terminal/Housing Retention Force. | Apply axial pull out force at the speed rate of 25±3mm / minute on

the terminal assembled in the housing. | 0.40kgf (Min.) | | 5-5 | Pin Retention Force | Apply axial push force at the speed rate of 25±3mm / minute | 0.50kgf (Min.) | | 5-6 | Durability | When mated up to 10 cycles repeatedly by the rate of 10 cycle per

minute. | Contact Resistance:40mΩ (Max.) | | 5-7 | Vibration | Amplitude: 1.52mm P-P Sweep time: 10-55-10 Hz in 1 minute Duration: 2 hours in each

X.Y.Z. axes. (Based upon MIL-STD-202 Method 201A) | Appearance No Damage. Contact Resistance 40mΩ (Max.) Discontinuity 1 μsec.(Max.) | | 5-8 | Physical Shock | 490m/s²{50G},3 strokes in each X.Y.Z. axes. (Based upon JIS

C0041/MIL-STD-202 Method 213B Cond. A) |

|

6. Environmental Performance And Others

| Test Description | Procedure | Requirement | | 6-1 | Temperature Rise | Carrying rated current load.(Based upon UL 498) | 30℃(Max.) | | 6-2 | Heat Resistance | 85±2℃,96 hours (Based upon JIS C0021/MIL-STD-202 Method 108A Cond.

A) | Appearance No Damage. Contact Resistance 40mΩ (Max.) | | 6-3 | Cold Resistance | -25±3℃,96 hours (Based upon JIS C0020) | | 6-4 | Humidity | Temperature: 40±2℃ Relative Humidity : 90~95% Duration: 96 hours (Based upon JIS C0022/MIL-STD-202 Method 103B Cond. B) | Appearance No Damage. Contact Resistance 40mΩ (Max.) Insulation Resistance 100MΩ (Min.) Dielectric Withstanding Voltage Must meet 4-3 | | 6-5 | Temperature Cycling | 10 cycles of: a) -25℃ 30 minutes b) +85℃ 30 minutes (Based upon JIS C0025) | Appearance No Damage. Contact Resistance 40mΩ (Max.) | | 6-6 | Salt Spray | Tin-plated 12 hours / Gold- plated 24 hours exposure to a salt

spray from the 5±1% solution at 35±2℃. (Based upon JIS

C0023/MIL-STD-202 Method 101C Cond. B) | | 6-7 | SO2 Gas | 24 hours exposure to 50±5ppm. SO2 gas at 40±2℃. | | 6-8 | NH3 Gas | 40 minutes exposure to NH3 gas evaporating from 28% Ammonia

solution. |

| 6-9 | Solderability | Soldering Time: 5±0.5 sec. Solder Temperature: 245±5℃ | Solder Wetting 95% of immersed area must show no voids, pin holes | | 6-10 | Resistance to Soldering Heat | When reflowing Refer to paragraph 8 Solder iron method Soldering Time: 5±0.5 sec. Solder Temperature: 370℃ ~ 400℃ | Appearance No Damage. |

7. Actuator Insertion/Withdrawal Force [Unit : kgf] | Circuits | Insertion (Max.) | Withdrawal (Min.) | | 1st | 3rd | 10th | | 02 | 1.84 | 0.41 | 0.15 | 0.12 | | 03 | 2.14 | | 04 | 2.45 | | 05 | 2.76 | | 06 | 3.06 |

|

Service:

Our company for the purpose of "arduous pioneering, pure devotees

of" "scientific management ,quality first ,service ,reputation

first" ,and continuously improve product quality and perfect

service , high-efficiency business management ,to provide customer

with quality products and satisfactory service .

HRT Offer good pre-sales & after-sales service & Strong technical

support

1. New Project: Strong technical and ideal support your new design

2. Existing projects: Try to help customer to save the cost to

offer the good quality product and save

3. time.

4. Free Samples:3-5 PCS of each part number

5. Customer complaint:24-48 hours reply 8D report

6. Warranty : 24 months ( Merchandise are promised to be promptly

returned, replacement,,or repair

7. kits if customers are not satisfied)